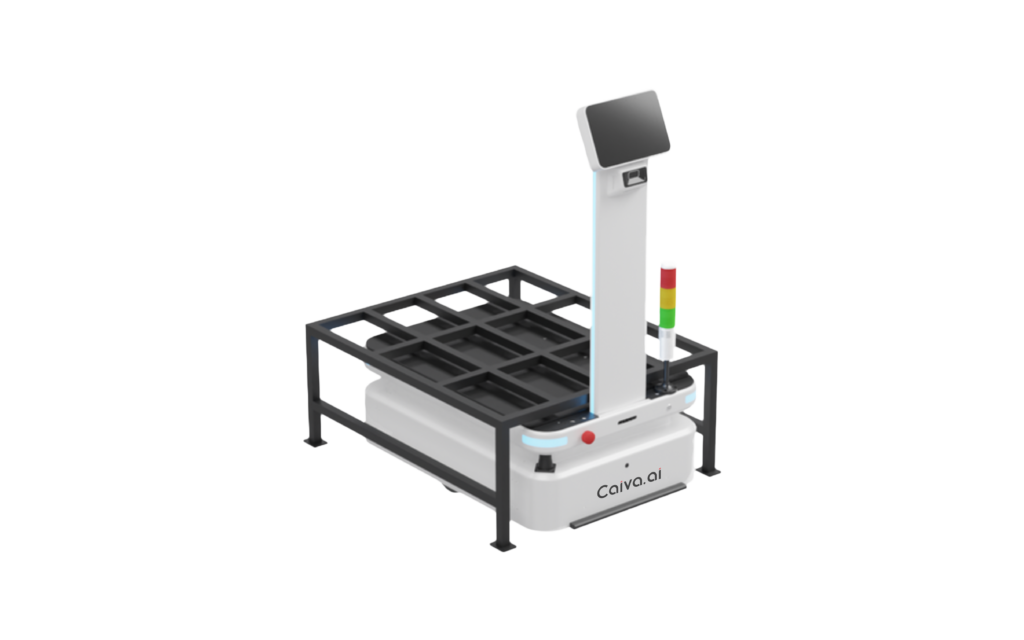

NAVIBOT

Meet Navibot,

Navibot is a cutting-edge autonomous mobile robot crafted for the hustle and bustle of industrial environments, offering a smart solution for moving materials from point A to B. Designed to navigate and operate independently, even in crowded areas, it can lift and transport items with accuracy. Its robust yet streamlined build allows for easy implementation, and it connects to the cloud for convenient oversight and planning. Notably, Navibot stands out with its ability to handle substantial loads up to 600KG, with lighter versions also available, making it a versatile asset for businesses aiming to automate their logistical workflows.

key feature

Autonomous Navigation

Navibot’s intelligence shines through its autonomous navigation capabilities. Equipped with advanced sensors and sophisticated algorithms, it can map its environment, plan optimal routes, and navigate industrial floors without the need for manual guidance.This autonomy allows for flexible and efficient material flow, adapting to dynamic warehouse layouts and production schedules

Real-time obstacle avoidance

Ensuring safe and uninterrupted operation, real-time obstacle avoidance is a critical feature of the Navibot. Its sensor suite continuously scans the surroundings, detecting and intelligently maneuvering around unexpected obstacles, be it personnel, equipment, or misplaced items. This proactive avoidance minimizes downtime and enhances workplace safety.

Precise lifting capabilities

The robot’s precise lifting capabilities enable accurate and secure handling of materials. Engineered with robust actuators and control systems, Navibot can lift and place items with millimeter-level precision, reducing the risk of damage to goods and ensuring seamless integration with automated storage and retrieval systems or production lines.

Durable & compact design

Designed for demanding industrial environments, the Navibot boasts a durable and compact design. Its robust construction ensures longevity and reliable performance under heavy use, while its compact footprint allows it to navigate effectively in confined spaces where larger material handling equipment might struggle. This makes it versatile for various industrial layouts.

Ease of use & Accessibilty

Ease of use and accessibility are enhanced through its integration with a cloud platform for remote monitoring and task scheduling. This connectivity allows users to track the robot’s location and status in real-time, schedule tasks, and analyze performance data from anywhere. This centralized control optimizes fleet management and operational efficiency.

Variants

The Navibot is available in models with 80KG, 120KG, 150KG, and 300KG payloads, offering versatility to meet various industrial needs. Its standout feature is a maximum payload capacity of 600KG, enabling the transport of heavier items and improving efficiency over lower-capacity robots.

These capabilities make the Navibot an ideal choice for businesses seeking reliable, automated logistics support—helping reduce labor costs, enhance safety, boost efficiency, and streamline operations.

All Scenarios Covered

Warehousing and Logistics

Manufacturing

Automotive

Healthcare

Food and Beverage

Aerospace and Defense

Product Gallery

FAQs

NAVIBOT autonomously navigates busy spaces, optimizing routes. Real-time obstacle avoidance ensures safe movement around personnel and equipment, minimizing collisions and improving material flow efficiency.

NAVIBOT’s precise lifting, with millimeter accuracy, minimizes damage to sensitive materials during transport. This accuracy also ensures seamless integration with automated systems for efficient downstream processes.

NAVIBOT’s durable, compact design allows maneuverability in narrow aisles and congested areas where larger equipment struggles, offering a versatile material handling solution for various industrial layouts.

NAVIBOT’s cloud platform enables easy task scheduling, remote monitoring, and real-time tracking. Data analysis provides valuable insights for optimizing workflows and improving overall logistics operations.

- NAVIBOT’s range of payloads (up to 600KG) provides scalable solutions for various material handling needs, allowing businesses to choose the most cost-effective configuration for their specific logistical requirements.

Support

Policies

- Shipping Policy

- Rufund Policy

- Warranty Policy

- Privacy Policy

- POC Policy

Explore

- Affiliate

- Become a Dealer